Yes, I know, I am behind everyone when comes to sterling silver clay :-). I guess it's simply because we don't have PMC distributor in Poland (anyone interested? ;-) ), so I rather stick to Art Clay. But last year when I got Rio Grande gift certificate for Saul Bell Design Award, I decided to spend it mostly on something that is not so easily accesible in my country, so PMC Sterling and Argentium :-). I already played with Argentium a little bit (fun!), but sterling clay was waiting and waiting... Finally I decided to try it.

Sooo, my plan for this post is to write a little bit about how did it go ;-).

Generally - I like the texture of this clay when it's wet - it's super fine, quite similar to PMC3 - a little bit like a bubble gum :-) (if compared to Art Clay). Long working time, darker colour than fine silver clay - blablabla everyone already knows these things - a lot of really great tests were published in various places.

What surprised me was how dried clay behaves. This material is undoubtedly designed for carving, and I don't really carve. I file. So at the beginning I was super annoyed by the fact that this clay, even when it's dried, is a little bit "buttery" and it clogs files immediately. So, in a way, I was forced to change my way of working, especially for this clay, but you know what - at the end I don't mind it. I learned a lot.

Another thing that I don't like is high shrinkage rate - I really don't need my pieces to become smaller. I can live with 10% of fine silver clays, but 20% is a little bit too much. And it comes with a price ;-) - bigger distortion. It turns out that it's not a problem in case of more or less flat pieces (all the pendants were ok), but in case of rings it is an issue. I had to reshape all the rings that I made so far, to make them round again after firing. I'll have to try firing plugs, but I don't like using additional stuff in firing process.

Yeah - as for the additional stuff - after a few first firings that left some carbon marks on backs of my pieces I learned (thank you Terry Kovalcik and Ros Wood! :-) ) that it's better to arrange firing in such a way that pieces don't have any direct contact with carbon - so cover them with a stainless steel mesh or something like that. With those first pieces I also tested soldering traditional sterling to fired PMC Sterling, and it works ok.

It seems that yes, this clay has its cons - no doubts about that -but the strength - it makes up for everything, and that's the reason why it's definitely not the last time I am using it. I want to use it more, especially for rings, but first I have to solve the distortion problem.

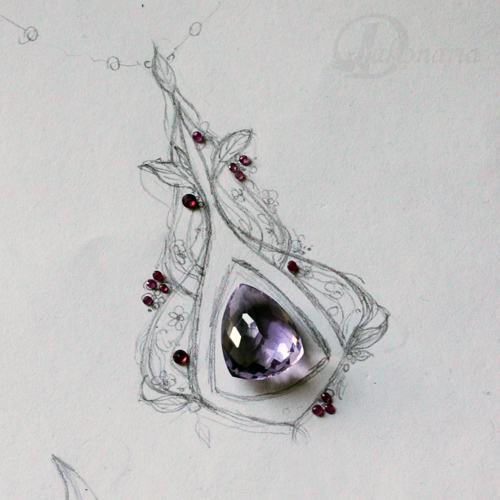

Here is another example of PMC Sterling work, mixed with sterling sheet and wire (the stone setting, bail behind it etc.) - "Dream Keeper". I cut sterling sheet in a shape which fitted exactly in between the ornaments on the back of the pendant, so it was easy to solder it. Then I soldered prongs on top of it and a bail on the back. It worked nicely.

If you are curious, here you can see a few steps of making my "Drawing down the Moon" pendant (the first photo), inspired by a Full Moon ritual. Someone asked in one of the internet groups, where did I get the mould ;-))))))), so I just thought that it might be interesting to show the process at least partially.

Here you can see some progress of making the face. I work mostly in an additive way. Then I take away some clay in "strategic" places ;-) with a file. I don't use any fancy carving tools etc. People who attended my classes know that I have just two favourite tools - something for cutting and a pointy file - this would be all.

Some more details. I didn't do anything to the face from that point - I was quite happy with the expression. I am still learning how to sculpt human faces and there is still a long way to go, but I feel I am finally starting to think about expressions and not only "how to make a face that looks more or less like a face" ;-).

Details, details. It's like building a tiny model :-). Adding a little bit, filing off a little bit. It's not easy, and it's not fast, but I think it's worth it. I just love this complex, three dimensional look I can get this way.

And some more building and filing - the piece might look quite openwork and delicate, but you might notice that each element is attached to something, really firmly, at least in two places.

Almost ready. I just added a little bit of 18K green gold inside the eyes - I wanted to create this feeling of her being "filled" with the Moon, with this otherwordly shine in her eyes :-).

And it was ready for firing. It turns out that manufacturer's schedule works just fine in my kiln, so I fired all my PMC Sterling pieces in two phases - first open shelf 538 °C for 1 h, and then buried in carbon 815 °C. for 1-2 h (depending on the size of the piece). After getting some marks from carbon in my first firings I make sure that I have some ceramic paper under the piece and stainless steel mesh above it. I don't mind quite long firing time at all - especially if I work on a piece for a few days. But I understand that this might be annoying for people who make a lot of simpler pieces.

Because of the green gold addition, in this particular case I repeated the second phase of firing twice. According to the manufacturer (Michelle :-) ), it requires double firing. You can read more about this material here. And I guess that this would be all for today ;-).